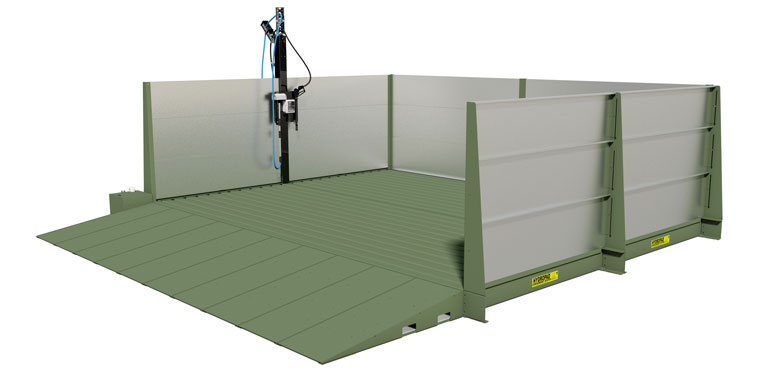

Equipment Wash Rack, Hydropads

Collecting wastewater and contaminants is job one for an equipment wash rack.

Hydropads array to create a portable wash pad that will meet job specific pressure washing equipment and wash water recovery requirements. Modular Hydropad systems are available with vehicle capacities up to 75 tons per axle. They are deployed above grade, require a minimal amount of site work and can be relocated when requirements change.

Build a wash rack with approach/depart ramps, overspray containment walls, awnings, remote equipment control stations, wash water collection and filtration options, drive over ramps for vehicle undercarriage access and perimeter catwalks.

Hydropads are building blocks for equipment wash racks. Take control of pressure washing equipment goals; get in compliance with EPA rules, promote an environmentally supportive 'green' company image and get the job done.

Hydropads Containment Pads, the best above ground wash pads.

- Hydropads are modular, simple to lay out and assemble. They bolt together to form an array tailored to application requirements. As applications grow, arrays can grow too.

- Hydropads feature all steel construction with a corrugated surface that ensures strength and integrity. Competing products with flat plate or diamond plate surfaces deform easily with loads typically found on wash racks. This creates puddles that retain water, oil and debris.

- The Hydropad corrugated surface sheds water and debris into channels that connect to side collection gutters. Debris is automatically flushed by high water flow rate in channels to side gutters. Flow channels allow flow under items being cleaned. No chasing water and debris around items and across surfaces of wash rack. Hydropad work surfaces stay clean and dry quickly to ensure superior footing for operators.

- Hydropads feature patented side gutters. Unlike competing wash racks with collection points inside wash rack perimeter, water and debris flow to side of Hydropad and into gutter. No chasing waste back and forth over a center collection point.

- Unlike a center gutter or sump, Hydropad side gutters can be serviced while the wash rack is being used and there are no heavy load bearing grates or covers to move before and after service.

- Side gutters are available with an optional variable speed conveyor system. Solids are discharged at 48" above grade. Fluid is filtered and discharged automatically with a sump pump.

- Because Hydropads have a side gutter, only one conveyor is required. Competitor's pads may require multiple gutters and conveyors, adding to the complexity, cost and maintenance.

- Side gutters are also available with a flip screen insert that is very effective in removing grass from turf equipment cleaning applications.

- Side gutters may be connected to a skid steer drive in clean out tray. This primary solid settling and collection system is inexpensive, robust and very effective.

- Hydropad capacities are unmatched by any competitor; 2, 12, 30, and 75 ton per axle ratings with 50 PSI or 125 PSI standard and up to 250 PSI point loading available.

- Patented self-standing wall design available in heights up to 8' with wind load rating of 70 mph. Taller walls for interior applications may be wind rated for exterior use when coupled with full canopy covers.

- Hydropads are protected with a powder paint process that starts with 5-step cleaning and phosphatizing followed by epoxy primer then a non-skid, textured, UV resistant polyurethane top coat. Coating system passes a 1500-hour salt spray test.

- Hydropads work in conjunction with the AUWS Automatic Undercarriage Wash System with flows up to 520 GPM to contain wash spray and track out.

- Customize Hydropads with undercarriage, side or top spray bars, inspection wash ramps, awnings, catwalks, and a wide variety of hose handling and control station options for operators.