Great Lakes Finishing Equipment, Inc. supplies the equipment and supplies for all your mass finishing needs. Our equipment includes vibratory bowls, tubs, continuous systems and high energy centrifugal barrel machines. Let our staff design and recommend the right finishing process for your application.

Frequently Asked Questions

What Types of Parts Are Best Suited for Vibratory Bowls and Tubs?

Vibratory bowls are ideal for small to medium-sized parts requiring uniform finishing, while vibratory tubs accommodate larger or more delicate components that benefit from linear motion.

Can Inline Finishers Handle High-Volume Production?

Yes, inline finishers are designed for continuous processing and are well-suited for high production rates of larger parts.

What Is Urethane Relining and When Is It Needed?

Urethane relining involves replacing worn linings in vibratory equipment to restore performance and protect the machine’s structure. It’s recommended when the lining shows signs of wear or degradation.

Does Vibratory Finishing Improve Surface Quality?

Absolutely. Vibratory finishing can clean, deburr, polish, and enhance the surface finish of manufactured parts, improving both appearance and functionality.

Standard round bowl finishers are the most common and versatile of all vibratory finishing styles of equipment.

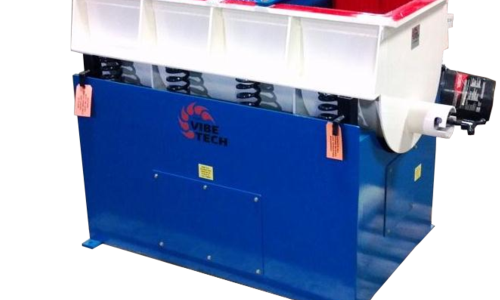

Tub finishers, or trough vibrators, are a versatile finishing machine for medium to large parts.

Vibratory dryers create a toroidal motion – a spiraling roll of media parts – and a vibratory motion that work together to achieve clean and dry part surfaces without leaving water stains.

Inline finishers are continuous process finishing machines that are designed for high production rates of larger parts.

Relines refer to the removal of old or worn out linings from your current finishing machine, inspection and repair of structure and replacement of the lining with a new polyurethane material.

The HZ Series Finishing Machines are the most economical, high speed finishing equipment available.

Vibratory finishing cleans, radii, burnishes, deburrs, polishes and improves the surface finish of a manufactured part.